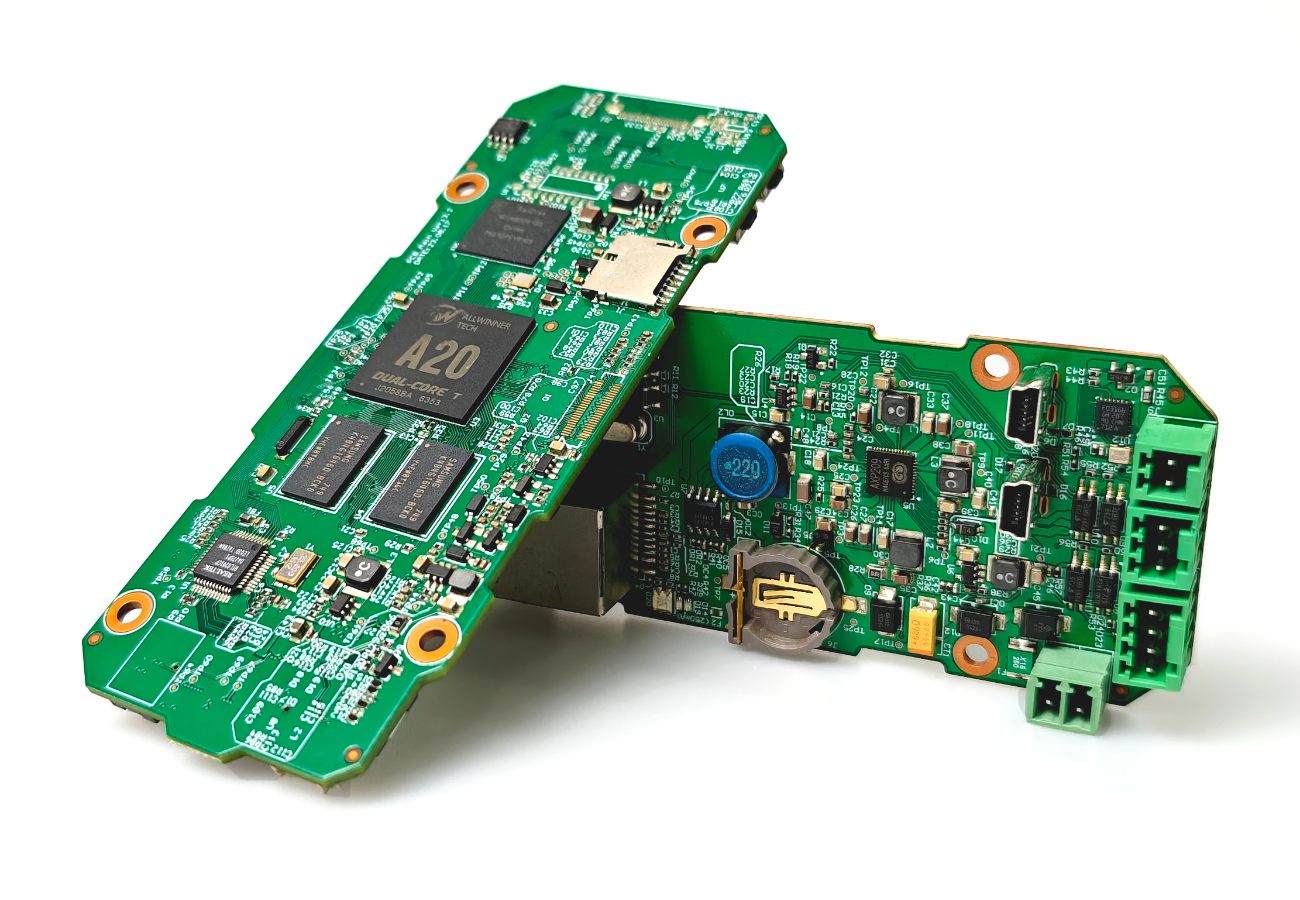

Fast and Reliable Prototyping for Modern Electronics

In the competitive world of electronics manufacturing, speed and precision are essential. A PCB prototype allows designers and engineers to test their ideas, validate circuit performance, and identify potential improvements before moving into full-scale production. By creating an accurate early version of a printed circuit board, manufacturers can save both time and money while ensuring the final product meets performance expectations.

Importance of PCB Prototype in Product Development

The PCB prototype stage is one of the most critical steps in the product development cycle. It enables the detection of design flaws, functional issues, or layout problems at an early stage. Without this process, companies risk producing faulty boards that could lead to costly recalls or product failures. A well-crafted prototype ensures that the design functions as intended, meets industry standards, and is ready for large-scale manufacturing.

Advanced Technology for High-Quality Prototypes

Modern PCB prototype services rely on advanced manufacturing technology to deliver accurate results quickly. High-precision CNC machines, automated soldering systems, and 3D design software work together to produce boards with exact component placement and clean circuitry. This combination of technology and expertise ensures that prototypes accurately reflect the final product, giving engineers confidence in their design before mass production begins.

Cost-Effective Prototyping Solutions

A professional PCB prototype service not only offers speed but also helps keep costs under control. By identifying design issues early, companies can avoid expensive modifications during mass production. The ability to test and refine a board in its prototype stage reduces waste, shortens lead times, and allows for better resource management. This cost-effectiveness is crucial for startups, small businesses, and established manufacturers alike.

Customization for Different Applications

Every project has unique requirements, and a PCB prototype can be customized to match the specific needs of a design. Whether it’s for consumer electronics, automotive systems, telecommunications equipment, or industrial machinery, prototypes can be tailored to different layouts, materials, and performance criteria. This flexibility allows engineers to experiment with various configurations and choose the most efficient design for their product.

Quality Control in Prototyping

A high-quality PCB prototype is the result of strict quality control procedures throughout the manufacturing process. From material inspection to final electrical testing, every stage is carefully monitored to ensure accuracy and durability. This attention to detail guarantees that the prototype not only works as intended but can also withstand real-world operating conditions.

Speeding Up Time-to-Market

In today’s fast-paced electronics industry, reducing development time is crucial. A well-executed PCB prototype accelerates the design verification process, allowing companies to move quickly from concept to market-ready product. By working with an experienced prototype manufacturer, businesses can shorten their production schedules and gain a competitive edge.

Choosing a Trusted Prototype Partner

Selecting the right manufacturer for your PCB prototype can make a significant difference in product quality and delivery times. The ideal partner combines technical expertise, modern equipment, and a commitment to customer satisfaction. This ensures that every prototype meets design specifications, is delivered on schedule, and helps bring innovative electronic products to life.